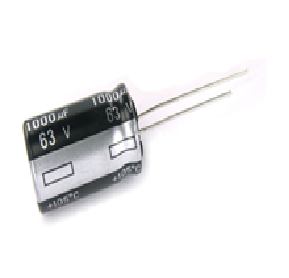

Electrolytic capacitor

An electrolytic capacitor (e-cap) is a polarized capacitor whose anode or positive plate is made of a metal that forms an insulating oxide layer through anodization. This oxide layer acts as the dielectric of the capacitor. A solid, liquid, or gel electrolyte covers the surface of this oxide layer, serving as the (cathode) or negative plate of the capacitor. Due to their very thin dielectric oxide layer and enlarged anode surface, electrolytic capacitors have a much higher capacitance-voltage (CV) product per unit volume compared to ceramic capacitors or film capacitors, and so can have large capacitance values. There are three families of electrolytic capacitor: aluminum electrolytic capacitors, tantalum electrolytic capacitors, and niobium electrolytic capacitors. The large capacitance of electrolytic capacitors makes them particularly suitable for passing or bypassing low-frequency signals, and for storing large amounts of energy. They are widely used for decoupling or noise filtering in power supplies and DC link circuits for variable-frequency drives, for coupling signals between amplifier stages, and storing energy as in a flashlamp. Electrolytic capacitors are polarized components due to their asymmetrical construction, and must be operated with a higher voltage (ie, more positive) on the anode than on the cathode at all times. For this reason the anode terminal is marked with a plus sign and the cathode with a minus sign. In addition they can only tolerate low applied voltages. Applying a reverse polarity voltage, or a voltage exceeding the maximum rated working voltage of as little as 1 or 1.5 volts, can destroy the dielectric and thus the capacitor. The failure of electrolytic capacitors can be hazardous, resulting in an explosion or fire. Bipolar electrolytic (aka non-polarized) capacitors which may be operated with either polarity are special constructions with two anodes connected in series.